Six Sigma in Service Sector – A Comprehensive Review

Introduction

I was attending a leadership workshop while working for an insurance broking organization. I mentioned how Six Sigma has major applications and benefits for the organization. The air of dis-agreement amongst my colleagues was total. The general consensus was that Six Sigma is for manufacturing companies. People quoted case studies. They named corporate successes like GE, Motorola, Honeywell and others. The point was nailed – these are all manufacturing organizations. They sell products, we sell services; Six Sigma works for them, not for us.

In that workshop, we chose not to argue it any further since it was out of context of the workshop per se. The above anecdote sums up the popular perception amongst people and organizations alike.

Six sigma in the manufacturing industry has been a credible story. Many organizations have realised benefits from embedding six sigma methodologies. Organizations have derived break-through strategies applying these methodologies. Combined with Lean, the methodologies have provided managers with tools to improve products. Also, embed a culture of continuous improvement.

Does that mean Six Sigma does not work in service environments? Perception says “no”, let’s do a reality check through this article.

Let’s start with reviewing how six sigma benefits industries.

Benefits of Six Sigma in Industries

Six sigma methodologies use statistics to measure performance. Goal is to measure variation within the output. Six sigma techniques focus on reducing the variation, and thereby reducing defects. This results in quality delivery of output to customers.

There are many benefits to organizations that embrace Six Sigma. Some of them are –

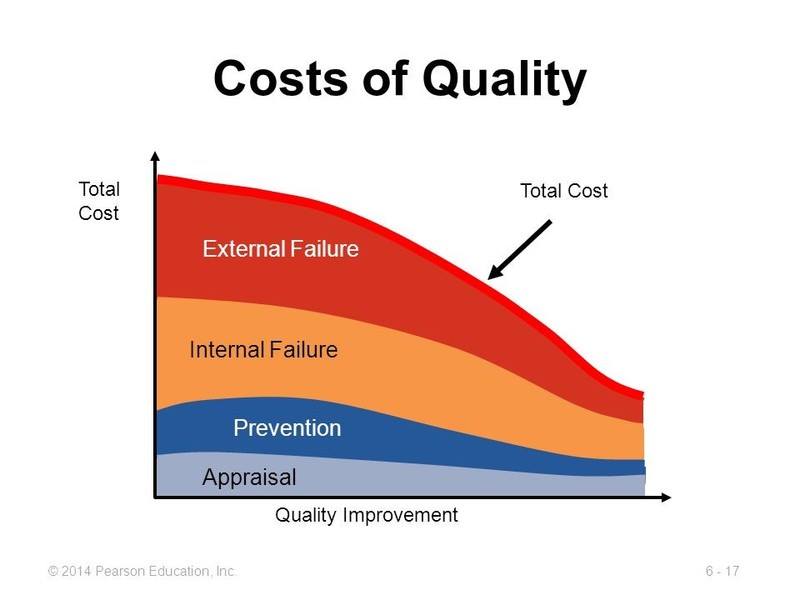

Increased profitability – This is a result of cost reduction. Cost reduction due to improvement in quality. Lower the number of errors, lower is the cost of re-doing the same. This is “Cost of Quality”.

Six sigma focuses on prevention or elimination of errors. This in turn, results in reduced cost of poor quality. An organization operating at 2 sigma or 69.2% yield incurs 40% of its sales on cost of quality.

A major part of this tends to be cost of poor quality. Lower the defect rate, higher the sigma and lower the costs. An organization operating at 4 sigma incurs 15-25% of its sales on cost of quality. At 6 sigma, it goes down to 0-10%. At this level, the costs are usually preventive and therefore essential. No wonder then, organisations measuring performance using six sigma techniques report financial gains consistently.

Image source: http://apppm.man.dtu.dk/index.php/File:CostOfQuality.PNG

Waste reduction - Waste reduction is another major benefit of six sigma implementation. We spoke about 8 Fatal Lean Wastes in one of my earlier blogs. Reduction of wastes like transportation, motion, overproduction, others results in efficient processes. Timelines for delivery improve and re—work reduces. Teams focus on meeting customer expectations rather than individual targets or goals.

Drives Customer focus - A famous literary author once quoted the phrase “he thought he knew”! This is a classic excuse made by people who seem to understand customer requirements. When business is flourishing and customers buy products, their confidence is high. "What they know" seems to work. When the markets are tough and sales are low, question is “why”.

Realisation crops up at this stage that we did not sell what the customer wanted. Very often customers know what they want the product to do for them. When selling they are sold as per specifications set by them. It is not necessary that a product meeting customer specification fulfils the need. Customers do not understand technicalities, need drives them.

Six Sigma applies methodologies like Voice of Customer to identify what customer needs. Aligning the product or service specifications to fulfil the need is the focus now.

From “I thought I knew”, it moves to “I know what the customer needs”.

Generates sustained improvement – In this era of start-ups and fast food, focus is on pace. Investors look for quick returns. New ideas emerge every day. Venture capitalists offer money loads to fund the promising ones.

9 out of 10 start-ups fail as per Forbes research. Reason being they do not look at all the aspects for a business endeavour. They ignore the “boring” stuff relating to business process, business model and scalability. Despite having a great product and superb team, they fail. The contrary applies to start-ups that succeed.

Start-ups need to innovate continuously. They are in a territory where there are bigger players and fierce competition. Deploying a six sigma program will enable a new entrepreneur to compete at all levels.

Six sigma strategies help build robust business processes, design new products and services. It helps sustain the improvement and innovation culture within the organization.

It benefits all organizations from large to start-ups. Six sigma strategies help sustained improvement over a period of time.

Sets direction and goals – To get the teams working together as a well-oiled machine is one of the biggest challenges for any CEO. Whatever the size of the organization, Six Sigma helps define a common goal for everyone.

“What does good mean” is a question asked by progressive customer-oriented organizations. Six sigma methodologies help in defining this. All parts of the organization think about quality delivery to the customer. Since the goal is common, it improves cohesiveness between the different teams.

Clear and defined measures exist across the organization. There is no ambiguity around performance evaluation as well.

Fosters Continuous learning and development- How many times have we heard this phrase “we are different”? In the past, different sections within organizations have worked as independent units. We call it “working in silos” now. What might be working well for one unit, another unit might be struggling with the same. Reason being lack of cross-pollination or sharing of knowledge within these units.

Six Sigma accelerates the sharing of new ideas within the organization. Unit measures exist and “good” is defined. It becomes easier to move people around the organization. Techniques like “Go See” and “cross process reviews” help in achieving this.

Ideation portals and practice sharing forums encourage people to share their ideas. Management recognises the best ones. Also gives opportunities to associates to be a part of the execution team. This leads to continuous development of people within the organization.

How does the service industry perceive Six Sigma?

Talk to anyone in the service sector on this. Their response is “Six Sigma is a manufacturing concept”. They are not entirely wrong. Six sigma evolved as a manufacturing concept. For decades, six sigma methodologies are reaping rich dividends within the manufacturing sector.

There are some views to support these perceptions. Let’s hear them.

“We are a people-driven sector”

That’s true! Service sector is about people and knowledge. People perform many of the processes that need industry and functional knowledge. Since people perform the tasks, there are no defects.

“All outcomes cannot be measured”

Service is about propositions. All propositions cannot be defined and measured. Every customer demands a unique experience. We give what they demand, and that makes us different.

“Six sigma is too techy”

Six sigma sounds very technical. Some of the statistical tools and techniques are not known to employees and leaders. How will they use it?

The above views are consistent across many service sector organizations. I can say so, since I have worked within the service sector for the last two decades.

Well, these are perceptions! The facts speak a different story.

How Six Sigma benefits the Service industry?

We need to de-mystify Six sigma tools and applicability for service organizations. The benefits are the same as any organization in any industry.

To re-iterate the benefits of Six Sigma -

-

Increases profitability – reduces waste

-

Improves customer focus

-

Generates sustained improvement

-

Sets direction and goals

-

Fosters continuous learning and development

Research shows that service organizations incur cost of poor quality. In some instances, it may be as high as 50% of the budgets.

Analysis reveals that less than only 10% of process cycle time is “productive work”. The remaining is waste, re-work and other non-value added activities.

Let’s take a case study shared by Genpact. Genpact is a global leader in transforming and running business processes and operations.

The case study covers the claims department of a leading motor insurance company. High cycle time of 112 days for claims processing was a cause for concern.

Using Lean Six Sigma techniques, Genpact identified the reasons for the high cycle time. They suggested measures for improving the same.

Proposed solutions were streamlining processes and centralizing administrative tasks. They suggested use of technology to automate certain activities.

Combined business impact of these changes could reduce cycle time by 12 days. Capacity generation can increase by 20% and business impact of $15M approximately.

Imagine you are a customer of this company! Would you not appreciate if your claims settle quick and without hassles? The obvious answer is “Yes”.

This is a classic case of how Lean and Six sigma techniques work. They help achieve sustained improvements and business impact. Most important, happy customers!

How to Adapt Six Sigma to service process?

So, are the issues with the service sector different from manufacturing? Do they serve customers in a different way?

Service organizations transact at a customer level. The sector’s nervousness around adapting six sigma is understandable. “Every customer is different” is what some service sector professionals say. That’s true! Six sigma might not apply to all service processes. With adjustments, it can apply to most service propositions or functions, if not all.

Let’s review some of the tips that will help a service organization adapt Six Sigma.

Review the process

“The devil lies in the details” is a phrase often used in corporate offices. Most often, at a higher level processes seem right. When you dig deeper, that’s where the devil hides.

Review current processes, encourage walkthroughs within the teams. You can start with a small team and conduct a thorough review. Look for opportunities to improve and simplify the process.

It is important that managers and subject matter experts buy into the merits of doing so. Unless you have all stakeholders on-board, desired outcomes will not be achieved.

Focus on pain points for the teams, look beyond the metrics at enablers as well. Tools like process mapping or affinity diagrams are simple tools to bring this to life.

What gets measured gets improved?

This is a challenge in the service sector. Within manufacturing, product specifications defined are to the smallest metric. Within a service environment, things are often not well defined. In such a scenario, measuring the same is difficult.

It is important to define “what good means”. Remove ambiguity from service definitions. Define clear measures for performance factors. Align them to customer requirements.

As Late W. Edward Deming, the quality guru said, “People don’t cause defects, systems do”. People perform service sector processes. The fact is that service defects still exist. It is important to define, measure and eliminate them.

Non-standard and fragmented processes make this a tough job. A bigger challenge is the lack of historical data to measure baseline performance.

The fact still remains – if you cannot measure it, how will you improve it. If you wish to run your business on facts and data, there can be no excuse. You will need to gather and analyse the data in a different manner.

Prioritize and define the problem

During the reviews, some problems might sound obvious and might seem inherent. It takes a while for people to realise that no problem is small or large at this stage unless we define the impact.

Over-excitement might creep up and you might have a load of problems defined. There is a risk at this stage for the entire Six Sigma programme to fall flat.

Look at issues from an outside-in perspective, putting on a customer hat. Detail your processes and align with customer requirements.

Use Six Sigma tools like CTQ drill-down tree or IPO-FAT for project identification. Control-Impact matrix or PICK matrix is a good tool to prioritize.

When you identify a problem, define it well. There might be a tendency to initiate too many small initiatives or certain big-bang improvements. The key is to focus on the priority ones to begin with.

Do not start with a problem that is unwieldy. This might raise frustration towards the later stages. You might not want to take this risk at the start of the program.

Focus on simple tools and application

Six sigma tools and statistical terms may sound techy to managers and associates. Especially when they are not introduced to the concepts before. Focus on application than tools to start with.

Tools like Root cause analysis and Five-Y analysis are easier to explain. They can be applied with minimal guidance or intervention. As the excellence culture seeps in, employees demand information on tools and approach. Giving it to them when they demand increases the chances of application. It’s better that they join the party when they are eager to do so; force might be counter-productive.

Six Sigma is a strategic approach

Six Sigma is often viewed as a series of improvement initiatives. Please remember that Six Sigma is a long term strategy. It is about transformation. The commitment of the leadership to the strategy paves the way for the future. It is about culture and approach as opposed to an endeavour.

It requires long-term commitment. The policies and organization structure needs to align to the approach. Profess facts and data and use the same for performance evaluation as well. Recognize behaviours aligned to the renewed culture. Reward outcomes achieved from the new approach.

Successful service sector companies – what are they doing

In financial services, organizations like Bank of America have succeeded in applying Six Sigma methodologies.

Bank of America used Six sigma techniques to manage a complex systems integration work. Result was a $1.85 billion pre-tax saving operational saving.

Marty Beltz was a healthcare instructor with American Society for Quality in Milwaukee. In the early 2000s, there were no books and no curriculum dedicated to the healthcare field. Earlier, her work was restricted to clinical units only. Now, it extends to support services in hospitals, rural clinics and the like. Beltz believes that Lean Six Sigma can reap 20 to 50 per cent return on investments to hospitals.

Mark Graban is the author of "Lean Hospitals: Improving Quality, Patient Safety, and Employee Engagement". Graban has observed that mid-sized hospitals from 250-300 beds achieved greater success with lean. It could be due to their small and manageable size. The merits of Lean Six Sigma within the healthcare sector are there for all to see.

The Dabbawalas or meal-box delivery people are another case in point. Delivering 200,000 meals a day in a busy Indian metro like Mumbai is a tough ask. There are so many things that can go wrong. Wrong destination, wrong meal-box, broken meal-box. Traffic snarls are a constant threat. Despite all these factors, they operate at Six sigma level. This means they make around one mistake in six million deliveries. They have been awarded a certificate for operating at six sigma level of efficiency.

Now, that’s some benchmark when it comes to service delivery. From financial services to education, healthcare, food and hospitalilty – the list is endless. All these service sector areas apply Lean Six Sigma to a varying degree. Some who have been investing in this for sometime are reaping the benefits. Others are viewing the merits of doing so and following suit.

In a nutshell

Service sector pioneers have busted the myth in the last decade. Six Sigma has significant application in the service sector. The case studies and corporate success stories are visible.

In a start-up environment as well, the principles apply with some variations. The important part is to look at this as a strategy, than an improvement initiative.