Six Sigma DPMO - The key metric to measure performance

I once saw an episode of "That 70's Show" (Season 1: Episode 18: Career Day) where Michael went to his father's office, trying to understand what he does for a living. His dad was a Six Sigma master black belt.

His dad showed him Line charts. Then he explained some statistical terms like chi-square test, standard deviation, and actualization median. In the end, Michael was more confused than before.

So, he decided that he'd tell everyone that his dad was a farmer.

Many statistical technicians, especially six sigma professionals, face this kind of problem. Not only is it difficult to explain their job to family and friends. But it's also challenging to explain to co-workers.

The problem is, we lack the understanding to keep things simple.

In this article, you'll understand what DPMO is and how it works.

As Henry Wadsworth Longfellow said, "In Character, in manner, in style, in all the things, the supreme excellence is simplicity."

Process Capability

We'll understand process capability more when we know WHO defines quality. Is the quality of a process or a product specified by the staff of the company?

Is it the designer, the quality control department, engineer, or the company's CEO?

The answer is NO, "the CUSTOMER always decides."

Hence, to provide an exceptional product or service, we must understand what the customer wants and build products and services with the customer's specifications.

For instance, you don't get to decide when a customer wants his Pizza delivered. And you can't impose your ideal phone to someone who has chosen what he wants.

The two implications of deciding for the customer are:

1. Under-specification

Where your product fails to meet the customer's expectations and most of the times, they return goods that don’t satisfy them.

Making adjustments would cost you additional expenses while ignoring dissatisfied customers can cost you your business.

2. Over-specification

In this case, your product has more than what your customers want and this might have no impact on their experience. If you sell at the customer's expected price, you'll run at a loss.

Selling at a higher price might make you deliver late. And you might lose your customers due to the lateness or cost.

Process capability is the measurement of how well a process is meeting customer expectations. With capability studies, you'll know

-

how well you're doing, relative to customer's specifications

-

ways to improve

-

if the improvements you've made are working

-

which suppliers are giving you the best service

Eventually, an excellent process capability can decrease the cost of poor quality (COPQ). The image that follows is a typical process capability road map.

Sigma Level

Industries use sigma level to translate their capability into a reporting metric. And it's termed universal because you can calculate it from either a continuous or discrete data.

You can determine the sigma level by the short term Z score. And for discrete data, you'll calculate from the defect rate.

You can also use the sigma level as a management reporting tool. You can convert any capability metric to a sigma level if necessary.

Sigma level can be used to define the capability of the primary metric

-

For continuous data, it's the expected defect rate or Cp, Cpk or Cpm.

-

For discrete data, this will often yield, DPU or DPMO

In the course of this article, you'll see how to calculate the sigma level for discrete data.

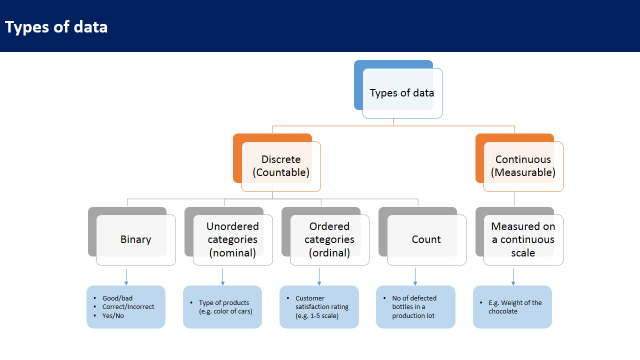

Type of data

The following table explains the types of data

It is important to understand the difference between the data types as the calculation for process capability or sigma level differs for data types in terms of calculation as well as understanding

Defect and Defective

Any feature of a product or service that doesn't meet the customer's specification is a defect. While defective is the term used to qualify a product that has a defect.

Let's assume you want to manufacture a mechanical part for an automobile. Imagine that its dimensions are specific and you made the length 12cm instead of 10cm.

This product is defective and if it's just the length, then it has one defect. But if two dimensions are affected, it has two defects.

And so on.

The number of defects that can occur in a product is known as defect opportunity (or simply opportunity). You can also say those opportunities are the only things you need to do correctly to satisfy the customer.

Each field in an insurance firm represents an opportunity. And each line of code in software is also an opportunity.

Capability for Discrete, “Count” Data

Defects per Unit (DPU): It is the ratio of the Sum of all the defects on all units to the total number of units

DPU = Sum of all the defects on all units/total number of units

You only calculate DPU when it is possible to measure multiple defects for a single unit. It works with the assumption that all "units" are identical. In other words, the opportunities for creating defects are fixed.

Cases where you should use DPU include

-

Multiple non-uniformities on a block of Paneer

-

Numerous design mistakes during a project

-

Insurance forms that can have errors in multiple fields

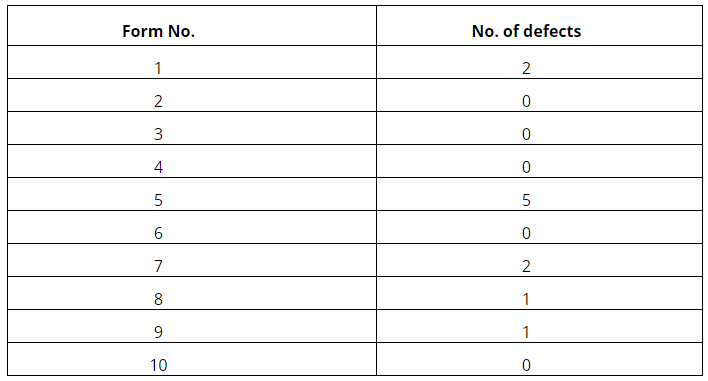

Example: A Bank in ABC city processes multiple insurances in a single day. Lately, the Manager decided to assess the performance of the process. He collected the sample of 10 forms and found the data as follows:

Now, to calculate DPU

Sum of defects on all units = 11

Total no of units = 10

DPU = 11/10 = 1.1

Which means they are producing 1.1 defects per unit in their current process performance.

Defects per Opportunity (DPO)

The DPU assumes that all units are identical. And it doesn't take into account the complexity of each unit. So, you must determine the defects per opportunity.

The first step is to calculate the opportunity.

Let's use the previous example. Suppose each insurance form has 50 mandatory fields. And not filling one can lead to the rejection of the form.

DPO = (Total defects) / (Total units X Opportunities per unit)

DPO = 11 / (10 X 50)

DPO = 0.022

This means in the current process, 0.22 defects are produced per opportunity.

DPMO

When the defects per opportunity become very low, organizations often express capability in terms of defect per million opportunities instead of DPO

DPMO = DPO * 1,000,000 (1 million)

DPMO = (Total defect / (Total units X opportunities per unit)) X 1000000

Let's go to our previous example again.

Here DPO = 0.022

DPMO = 0.022 * 1000000

DPMO = 22000

Hence per 1 million opportunities, the bank is creating 22000 defects.

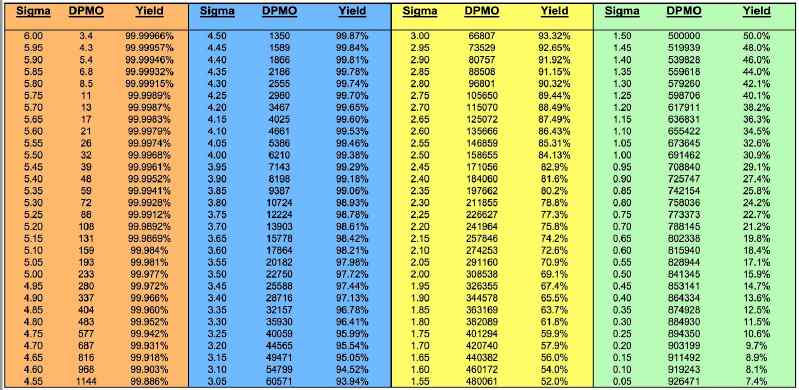

DPMO to Sigma Level

You can use the table below to calculate DPMO to sigma level.

From the table above, you can conclude that the current sigma level of the insurance process is between 3.50 and 3.55.

Converting DPO to Z-score with Minitab

You can convert DPO value to Z-score with the help of Minitab. Then use that Z-score to find out the sigma level of the process.

All you have to do is,

-

Go to Graph > probability distribution plot…

-

Select View probability and click OK

-

For distribution select Normal with mean of “0” and a standard deviation of “1” (Assuming the process to be normal)