How to start a Six Sigma project?

The Six Sigma project deals with Six Sigma methodology like DMAIC, DMADV, and DFSS, Business Process Management and Statistical tools, these 3 make the Six Sigma Management System. We cover the methodology and statistical tools in Six Sigma courses, like Green Belt, Black belt etc. In this article, we are not going to discuss these methods and Statistical tools, as these form the technical side of the Six Sigma approach.

We will talk about the Management system, which we need to use, while successfully running the Six Sigma project. This is a more real-world approach, and we need to see all the aspects of the management and their reluctances. Apart from this, we will learn, how a Six Sigma gets a kickoff.

First, we will see all the reluctance, while proposing for the Six Sigma projects, and then we will see what all are the things we need to capture and present it in front of the stakeholders to convince them to approve the Six Sigma projects.

Any Six Sigma problem, which starts with the practical problem or opportunity will definitely get a practical solution. The Six Sigma Management system is robust and designed to guide an organization’s performance improvement initiatives at all levels.

While starting the Six Sigma project, there are many reluctances we need to encounter. We will talk about those reluctances as below:

Organisational Barriers

- Unwilling to adopt the change – “Change is only constant”, however, we as humans are not always ready for a change. Therefore, pursuance for change is required while we submit a project proposal, we need to update the stakeholders for the change, which will happen after the improvement.

- In the problem-solving approach, we mostly get the reactive approach and need to deal with the process experts to make them agree to a new approach.

- Sometimes, we will not get the leadership support from operations for the project, we should understand their reluctance issues and pursue them accordingly.

Handling the Organisational Barriers

- Creating a project vision, and aligning with the company’s goal and vision.

- Creating the new roles and opportunities for the operation managers.

- R and R (Rewards and Recognitions), for people whose are contributing more and to set up an example for others.

- Certification for people who are involved in a project and conduct the basic training.

- Develop the feedback sessions to collect all the feedback received from all external and internal clients (including employees at all levels).

- Sort out the roles and responsibilities for all members who involve in the project by ARMI and RASIC.

Explore more: Six Sigma for Business Excellence

Change management and handling the reluctances

For any organization while starting the Six Sigma project, we face reluctance and resistance in the process, which can be of any type, generally, it is divided into 4 main categories i.e. Technical, Political, Organisational resistance or Individual resistance.

In the technical resistance, employees are not willing to work in different methods, change acceptance for any employee is not easy, for them adjusting in the new environment from the existing one is a difficult process. We need to focus on high-level concepts which can help them to build their capacity to work on another work environment.

Political Resistance and Organisational resistance: Sometimes, changes make employees insecure, they feel in a new environment they will not be able to put their expert knowledge and that they might lose their authority in the organization.

Sometimes, some individual employees fear new changes.

While running a project, you should involve the senior associates and keep them in confidence. The fear of employees can be decreased by their mere involvement in the project.

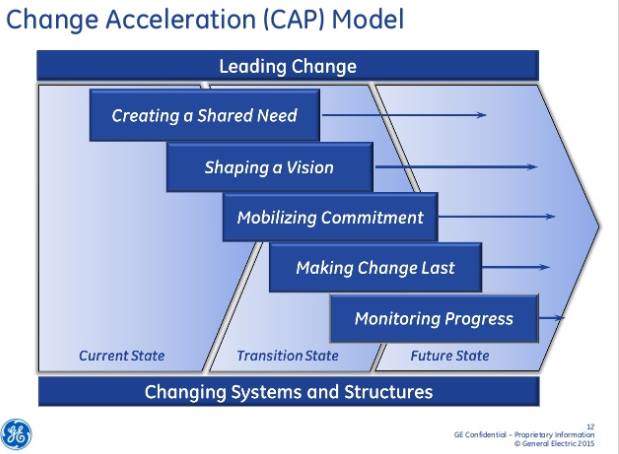

GE company used the CAP tool since they believed the success of any project not only depends upon the technical solution, sometimes it is required that people should be ready to accept the project and accept the new changes.

Creating a shared need

This is the reason for running a project. It should be aligned with the vision of the company. It can be in alignment with the 3Ds: Data, Demonstration, and Demand.

Shaping a Vision

The vision should be clear and aligned with the stakeholders' vision, i.e. the company’s vision.

Mobilising Commitment

We need to make a strategy to win the support from all the key stakeholders, for that we need to first convince the lower level management, since the upper-level management relies on them only, if we succeed to convince the lower level, it will be easy to buy out from the upper-level management.

Making Change Last

The change can be consistent if it is accepted and used by the whole team. The best practice should be shared with them, so that the changes will be inherently acceptable, not just for a time being but always.

Monitoring Progress

While monitoring the change, one should see the difference between before and after. The measurement must be clear enough to show the success of the project.

Project Opportunity

Identify the business and their problems/opportunity for Improvement.

The Six Sigma opportunity can be identified in different ways - by Voice of the customers (Reactive or by proactively conduct the survey or focus group). Or it can be by the voice of the process, or by making a control chart to check if the process is stable or not.

These are the ways we can find the Six Sigma opportunity, we can get in other ways also while doing the Gemba to get the process improvement opportunities.

The improvement area could have a large scope, so it would be better if we can cover a small improvement area and run the project accordingly.

While running any project, it is necessary we must not know the solution, if we have the solution in hand, we can directly fix issues without any hindrance.

The Six Sigma Methodology is a kind of scientific approach which is based upon the Metric Hypothesis.

As we all know, the main focus of the Six Sigma is to realize the customer value.

The customer-driven organizations have the qualities as listed below:

- They focus on flat hierarchy, i.e. every people have authority at their level to take decision for organization benefits.

- Manage the communication by regular meetings and focus groups.

- Top Management should be supportive and understanding.

- Must be active on customer’s feedback and take actions accordingly.

Read more: Quick Tips To Enhance Productivity In LSS Projects

Recognizing the project opportunity

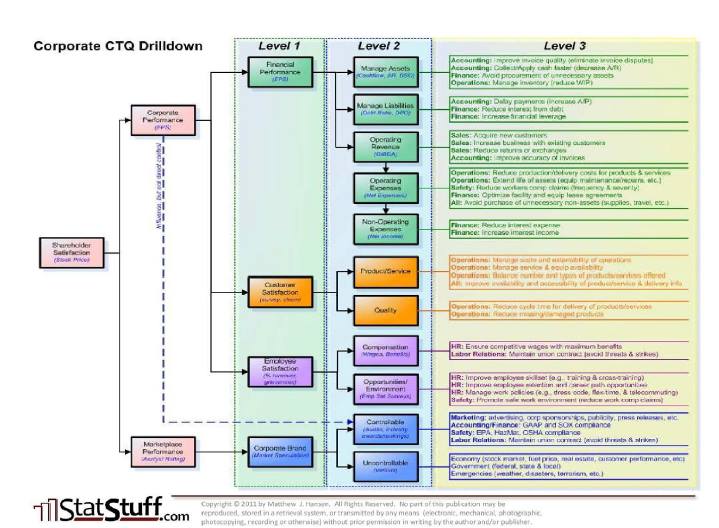

To recognize the project opportunity, we should go by Corporate CTQ drill down tree. This tree helps us to understand the hierarchy of the importance of the business down to the lowest importance for the business.

Though we consider the end user as the most important customer, however in the corporate world the business owner or stakeholders are the most important customers.

Every business has a different process and every process will have some issues or drawbacks, we need to prioritize, by the CTQ drill down, in which we need to work and improve the process.

Image Source: www.Statstuff.com

It gives the whole CTQ drill down info. Then how does it work? It is segregated into 3 Levels:

Level 1 is the categorized the department for the corporate.

Level 2 indicates the sub-department of the department.

Level 3, here we get the actual issues.

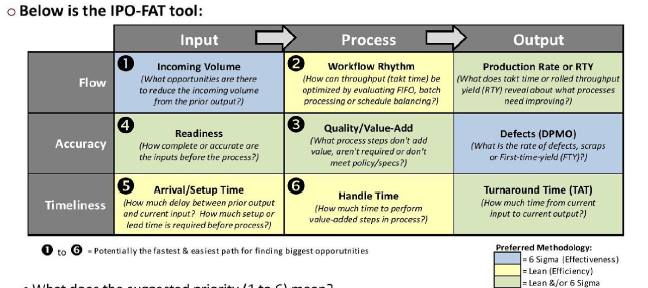

The other way of finding the project by IPO FAT tool or Gemba. In these two methods, we do the brainstorming sessions. Once we receive all the ideas, we can segregate into the Lean or Six Sigma projects.

Image Source: www.Statstuff.com

Project Scope

Once we decide the Project area, next we need to find the scope of the project, which is a very important part before starting the Six Sigma project. It gives the boundaries to the project and mentions which are the things that will be “out of scope”.

As a matter of fact, we cannot improve the whole process at once, we need to make project boundaries so that in a small way, we could improve the whole process.

A project scope is defined by the consultant along with the sponsor. Also defining the scope creep, during the course of the action we could find the lack of people support while doing the creep, we can take the approval to extend the number of people.

Project Valuation

Before presenting in front of the Senior management, the process valuation is required in three areas:

- What is the issue?

- What are the supports?

- What are the financial benefits of the project?

- What is the issue/problem?

What is the issue?

What is actually the process facing issues in the system, before that, we need to provide the whole business scenario. The problem scope needs to be framed properly and what are the areas which would be covered by the project.

What are the supports?

In Six Sigma projects, the support from whole operation team is very important at all levels. We need the support from Stakeholders to the associates, who are working in the process.

We need to see the KPI (Key Performance Indicators) and what all are the things which will impact our process.

What are the financial benefits of the project?

The financial benefits we can see in different ways. ROI, Max-Min analysis, NPV, and IRR. The financial benefits can be seen, direct and indirect. Direct benefits mean the cash flow we receive, which has a direct impact on our project.

The direct benefits impact on the cash flow, or we can see the financial benefits. The indirect benefits, which will not be directly impacting to the cash, however which impact other things.

You may also like: How To Avoid Pitfalls In A Six Sigma Project And Deliver

ROI- Return on investment, how much would be the return on investment. If we run the project, some cost would be involved, we see in return, how much we receive after the project.

Min – Max Analysis

By the Min-Max analysis, we check, if we involve the money in the project, a minimum of how much we will receive by this. If the project’s minimum benefits are substantial, then the project opportunity could be worthwhile. And if the maximum benefits are not substantial, we can avoid running the project.

Net Present Value (NPV)

We need to check the net present value to run the Six Sigma project. It is the method by which we calculate the net present gain as per future cash flows.

Future Value = present value (1+r)^t

Internal Rate of Return (IRR)

The IRR is defined as the rate of return which equates the present value of future cash flows with the cost of the investment. In Excel, we can calculate the IRR value by “=Irr”.

Team Formulation

The Six Sigma team formulates into 4 steps i.e. Forming, Storming, Norming and Performing which are given as below:

- Forming

- Storming

- Norming

- Performing

-

Forming

In the forming stage, the Six Sigma team depends upon the leadership guidance and their directions. The whole team work, their purpose, and the scope of the work clearly depends upon the leader. Here their roles and responsibilities get divided, so everyone should know what all are the expectations and the team tries to keep up with them.

Here, leaders must try to find answers for all the queries which lie on each and every team member ’s mind and make them satisfied.

-

Storming

Here the internal Six Sigma team gets formulated, and they try to adjust with each other and understand the roles and responsibilities. Here the team actually focuses on how to accomplish the project goals. The major focus is on the team bonding. At this stage, we need to deal with everyone’s emotions and their experiences and make them satisfied.

-

Norming

In the norming stage, group identity and cohesiveness among members is established. Members achieve a sense of belonging and become comfortable sharing ideas and feelings and giving or receiving the feedback. At this stage, the team discusses the working style.

-

Performing

The Six Sigma team becomes an interpersonal force of interlocked roles and shared commitments. The performing team deals with the obstacles, challenges and any setbacks. They try their level best to achieve over the given target.

Project Scheduling

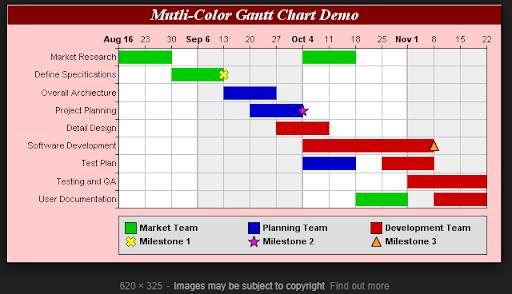

After forming the team of the Six Sigma project, the next step is to create the milestone for each phase (DMAIC) of Six Sigma project. Try to put the milestone clear, so that there is not much confusion in this respect.

And if we complete any phase before the given time frame, try to utilize the time left in another phase.

The general milestone dates should be as below:

Define – 1 Month

Measure – 1 Month

Analyse – 1 Month

Improve – 1-2 Months

Control – 1 Month

We should not make a project plan beyond 6 months time frame. The Define phase could take more time.

Gantt Chart

The project schedule can be done of two types –

- Gantt Chart

- PERT CPM Diagram

Gantt Chart

A Gantt chart shows the relationships among the project tasks, along with the project task time. The horizontal axis shows the units of time, and the vertical axis shows the project milestones.

Image Source: https://www.monkeybreadsoftware.de

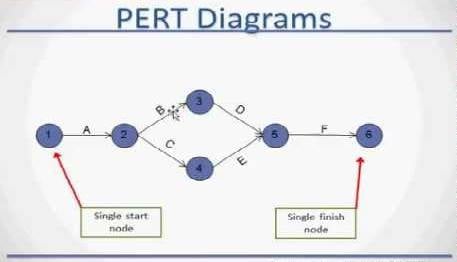

PERT CPM Diagram

The PERT CPM consists of 4 basic phases, i.e. Planning, scheduling, improvement and controlling. While using the PERT CPM for a given activity, the Cost per unit of time saved is found by the formula as (Crash Cost – Normal cost)/(Normal time – Crash Time)

Image Source: https://bit.ly/2OfzIHR

Conclusion

So here we can see, the Six Sigma project is not only the statically approach, it is beyond the statistics and techniques since we not only use the techniques, but we need to focus more on the management side as well to understand the clients and customers needs. So before starting any project, we first need to work upon these things and keep in the mind how to make the changes and make people accept the changes. Since the best solution cannot solely bring in the project success, their acceptance and utilization are also essential for the process members.

Kickstart your Six Sigma training | Enrol now!