An Introduction to Total Productive Maintenance

Machines help with all production processes. So organizations rely on machines for almost everything production-related.

Organizations don’t like machines, equipment, or their instruments breaking down. This concern is for the reason that breakdowns cause production disturbance.

To eliminate this disturbance, you want to stop the breakdown of the machines. Hence the use of TPM for planned maintenance.

How TPM Started

The Total Productive Maintenance (TPM) is a method for business process improvement.

TPM originated in Japan in 1971 by the Japanese Institute of Plant Maintenance (JIPM).

Other companies eventually adopted this maintenance practice and improved on it. At this point, TPM had gained standard structures.

The process uses a comprehensive set of tools and techniques to eliminate all losses. It’s gained adoption across organizations and throughout the value stream.

The Aim of TPM

TPM integrates the equipment maintenance management concept to improve the maintenance process. It concentrates on process improvement by enhancing machine productivity.

The primary aim of TPM is to increase machine availability to boost productivity.

The starting point of TPM is that everyone in the company is responsible for the maintenance of the machines. And organizations buy machines only for the uses they’d intended for them.

For machines to work appropriately, they should receive the highest level of maintenance possible. And in this context, “maintenance” includes “improvement.”

With maintenance in order, organizations can find, and free machines of any hidden losses.

TPM aims to reduce six significant losses in the maintenance process. These losses were captured in the Overall Equipment Effectiveness (OEE).

The OEE is a measure to address losses.

TPM works to ensure an OEE score of 100% to attain Perfect Production. In that case, the machines work in full speed and deliver the highest quality products.

The goal of the TPM is to achieve the perfect production with

- Breakdowns eliminated

- No Small Stops or Slow Running

- Zero Defects

Six big losses

1. Equipment Failure

Equipment failure is production loss due to equipment that won’t work. Production may not have worked because a part of the machine is faulty.

Unplanned stops in the production or the downtime of the machine are equipment failure. Common equipment failures are tool failure and breakdowns.

At other times, production stoppage is due to no operators or machines available.

2. Setup and Adjustments

Setup and Adjustments is the production loss due to changeover or equipment adjustments. This production loss also affects the availability of the machine.

This is a planned stoppage of the production system. Although intentional, it’s still responsible for the loss in machine availability. An example of the setups and adjustment loss is changeover.

This loss can be addressed with the help of the SMED program. SMED is short for Single Minute Exchange of Dies. It reduces setup time.

3. Idling and Minor Stops

Idling and Minor Stops is production time-loss where the equipment stops for a very short time (one or two minutes).

The operator will solve this interruption by them themselves. The loss affects the performance of the machine. Examples of Idling and Minor Stops are

- Material jam,

- Obstruction in the flow,

- Incorrect setting,

- Blocked sensors, and

- Periodic quick cleaning.

These stoppages are usually less than 5 minutes and do not require maintenance personnel. Production continues after the operators fix it.

4. Reduced Speed

Reduced Speed is the production time-loss in which equipment runs slower than the Ideal Cycle Time.

The ideal cycle time of production is the fastest time equipment takes to produce a unit of item. This delay-type also affects the performance of the machine.

It’s also called Slow Cycles. Examples of reduced speed loss are

- Dirty or worn-out equipment,

- Poor lubrication,

- Substandard materials,

- Poor environmental conditions,

- Operator inexperience,

- Startup, and

- Shutdown

5. Process Defects

Process Defects is the loss in productivity due to a defective part while making the production. This loss affects the quality of the production process.

Defects include Scrap and Rework. Some examples are

- Handling errors,

- Incorrect settings,

- Products that don’t meet a customer's specifications

6. Startup Rejects

Startup Rejects refers to the loss in productivity because a machine part became defective during startup.

This loss will also affect the quality of the production process.

Examples are

- Suboptimal changeovers,

- Incorrect setting and

- Equipment with warm up cycles

Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness is the score comprising of

- Availability of the machine,

- Performance of the machine, and

- Quality of the production process.

OEE= Availability x Performance x Quality

- The ideal OEE production score is 100%

- World-class manufacturer score starts at 85% OEE

- Meanwhile the typical manufactures OEE score is 60%

- Manufacturers without TPM or Lean programs have OEE scores that starts from 40% score

Availability

Availability is an OEE measurement for the loss of machine availability. It measures planned and unplanned stops.

This measurement helps improve the uptime of the machine. It deals with the Equipment Failure as well as Setup and Adjustments.

Availability= (Planned Operating Time – Stop Time) / Planned Operating Time

Planned Operating Time = Available Time – breaks

Stop Time = Equipment Failure time, Setup and adjustment time

Performance

Performance measures OEE for loss of machine performance. It measures the Cycle Time of the production.

This metric helps improve the cycle time of product manufacturing. It deals with the Idling and Minor stops and Reduced Speed.

Performance= (Ideal Cycle Time x Total Count) / Run Time

Total Count = No of product produced

Ideal Cycle time = Time to make a product

Run Time = Planned Operating Time – Stop Time

Quality

Quality is an OEE measurement for the loss of quality in the process. It measures the first-pass part by the machine. And this metric also helps improve the quality of the machine.

It deals with Process defects and Startup Rejects.

Quality= Good Count / Total Count

Good Count = Total no of products produced - Defects

Total Count = No of products produced

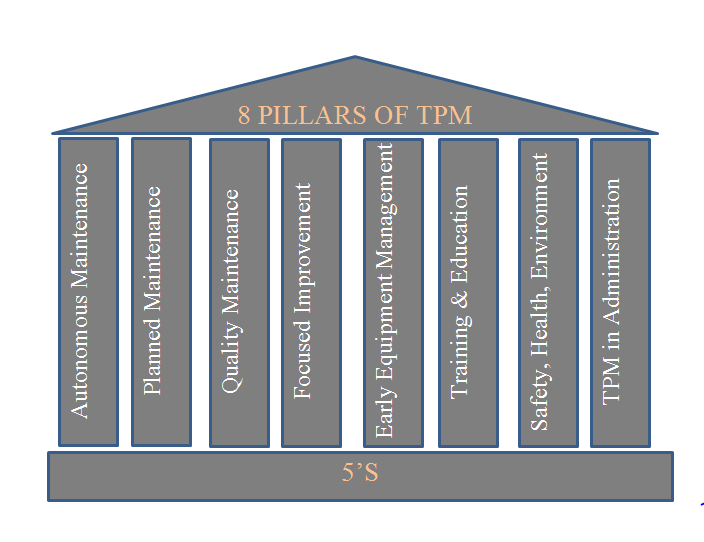

Pillars of TPM

The eight pillars of TPM are the techniques used to implement the TPM to improve OEE.

By implementing these techniques, availability, and performance of the machines improve. And machine defects produced also reduce.

The pillars covered here are:

- Autonomous Maintenance

- Continuous Improvement

- Preventative Maintenance

- Early Management of New Equipment

- Process Quality Management

- Administrative Work

- Education & Training

Autonomous Maintenance

Autonomous Maintenance means the operator monitors the equipment’s condition and work areas. This process includes that the operator maintains and cleans the machine daily.

The Autonomous Maintenance process increases the skill level of the worker since they gather knowledge about the workings of the machine. Also, AM reduces the investment of the organization because it makes the machine reliable.

This process also increases the lifespan of the machine through constant monitoring and maintenance.

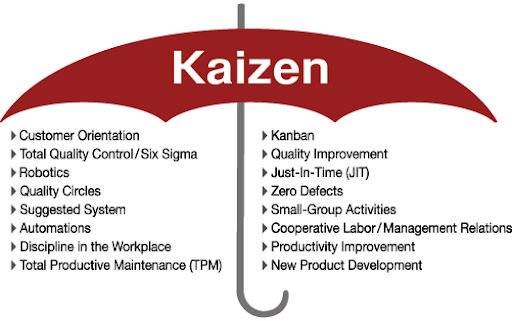

Continuous Improvement

Continuous improvement is also known as Kaizen in Japanese. The concept is based on improving a process, that in turn, helps an organization improve quality and productivity.

Kaizen is the improvement of activities that run on the PDCA cycle. It comprises

- Identifying,

- Analyzing and

- Eliminating NVA in the process.

Kaizen teams are formed with people from various disciplines. A machine’s problems are identified and improved with a Kaizen event.

At Kaizen events, employees map the current state of a process and then base their improvement of that system on the desired future state of the system.

Teams that use Kaizen start with identifying the root cause of their problems and then try to resolve it.

Planned Maintenance

Planned maintenance is a maintenance activity that precedes the breaking down of a machine. This prevents machine downtime.

It’s also called Preventive Maintenance.

Team leaders set preventative maintenance tasks schedules, and then assign them to operators.

Early Equipment Management

Early equipment management aims to build a maintenance system in the product design stage itself to drive high efficiency.

EEM helps machines run better and keep them low maintenance. EEM works like autonomous maintenance.

Process Quality Management

Quality management improves product quality by ensuring that a machine detects failure for itself during production.

Catching errors early means more reliable production processes and higher product quality.

Training and Education

Training and education provide the knowledge necessary to operate the machines to full capacity.

The benefit of training and education is that trained operators and managers deliver their duties better. Operators can carry out maintenance activities that would have required a maintenance team.

Office TPM

Office TPM ensures that people carrying out supportive functions understand and apply Lean principles in their operations. This process helps implement TPM activities, boosts system efficiency, and reduces NVA.

TPM principles can also be applied as stand-alone techniques to improve the efficiency of supportive functions. Thus, the Pillars of TPM helps to improve the system.

OEE provides the standards for ascertaining the availability, performance, and quality of a machine. A process that’s done by monitoring and eliminating the six big losses.

The ultimate goal of an organization is to end all production breakdowns, defects, and delays.

Looking for a change? Get Lean Six Sigma Certified